Current Opportunities

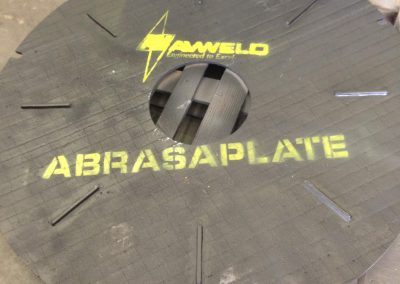

Avweld’s AbrasaPlate® is a high quality chrome-carbide weld overlay (CCO) wear plate, used for applications requiring severe abrasion and wear resistance. It is available in various dimensions of clad hardfacing overlay, and mild steel backing plate. It is easy to work with, can be rolled, welded, and formed.

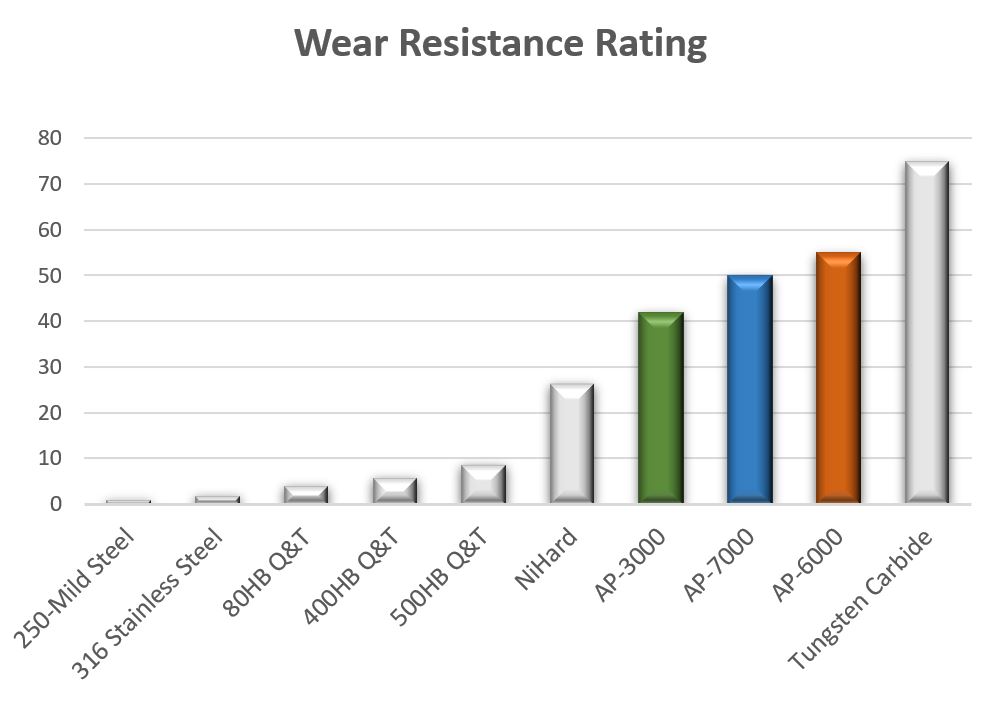

It is available in standard sheets of up to 2.2×3.0m, or cut to size for a specific application. Avweld can supply with studs welded or holes drilled. AbrasaPlate® is commonly used for a replacement in applications where Q&T plate (such as Bisalloy or Hardox) is inadequate. Typical life extension over Q&T 400 is a minimum of 4 times, and can be up to 10 times, depending on application.

Avweld have been the East Coast of Australia’s leading Wear Plate distributors for over 30 years.

<Download AbrasaPlate Wear Plate Brochure ![]() >

>

AVAILABLE GRADES

- AbrasaPlate® AP-3000 – High quality general purpose plate designed for medium impact and high abrasion. A high volume of hexagonal chrome carbides in a tough austenitic and martensitic matrix.

- AbrasaPlate® AP-6000 – Uniformly distributed hexagonal chromium and complex carbides imbedded in tough austenitic and martensitic matrix for high temperature applications.

- AbrasaPlate® AP-7000 – Increased chrome carbide content is achieved through the submerged arc welding process, resulting in higher abrasion resistance.

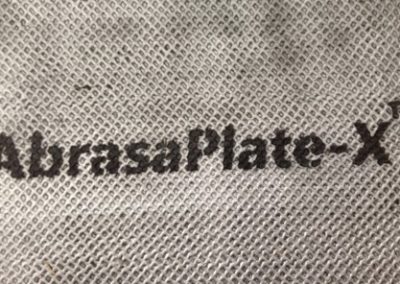

- AbrasaPlate®-X – A 2-3mm thick cross hatch weld overlay on top of any standard plate. Increases impact resistance and allows the plate to become self protecting using a ‘rock box’ effect.

- AbrasaPlate® CF – A high quality compound weld-overlay hardfaced plate. The chrome carbide overlay is applied in a unique fashion which results in a hard, wear-resistance cladding, despite being crack free

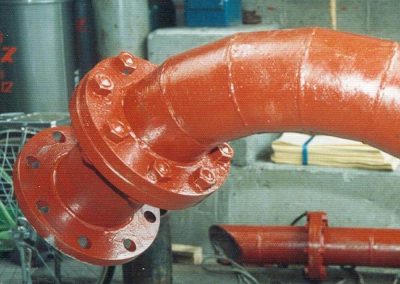

- AbrasaPipe® – Internally hardfaced pipe designed for abrasion resistance. Prevents wear against fine particle slurries and dust.

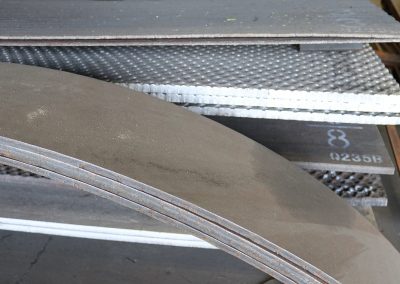

| COMMON SIZES | ||

|---|---|---|

| 3 on 3 | 6 on 8 | 12 on 8 |

| 4 on 4 | 8 on 6 | 12 on 12 |

| 4 on 6 | 8 on 8 | 17 on 12 |

| 6 on 6 | 9 on 10 | 20 on 12 |

| Other sizes on request | ||

| COMMON APPLICATIONS | ||

|---|---|---|

| Chutes | Truck Beds | Buckets |

| Ducts | Screen Plates | Hoppers |

| Pump Casing | Transition Segments | Crushers |

| Fans | Elbows | |

Benefits of AbrasaPlate

♦ Weld overlay hardfacing on mild steel backing

♦ Higher abrasion resistance compared to stainless steel, Quenched & Tempered steel

♦ Higher abrasion and impact resistant than ceramic

♦ Easy to form, weld, roll

♦ Can be cut by plasma

♦ Different grades for different applications

♦ Excellent impact and abrasion resistance

♦ Available in sheet form, replaceable wear liners or fully fabricated assemblies