Laser Cladding

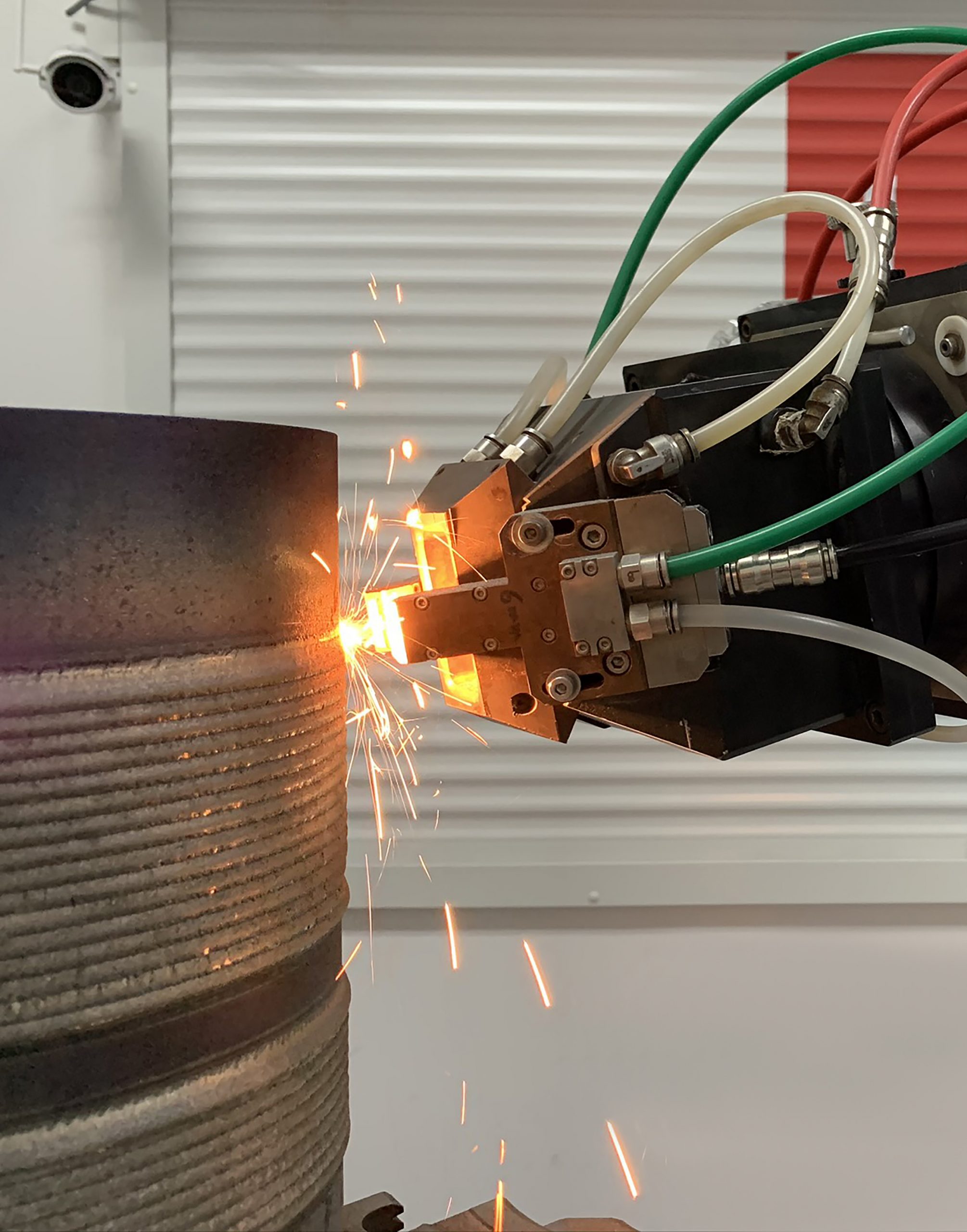

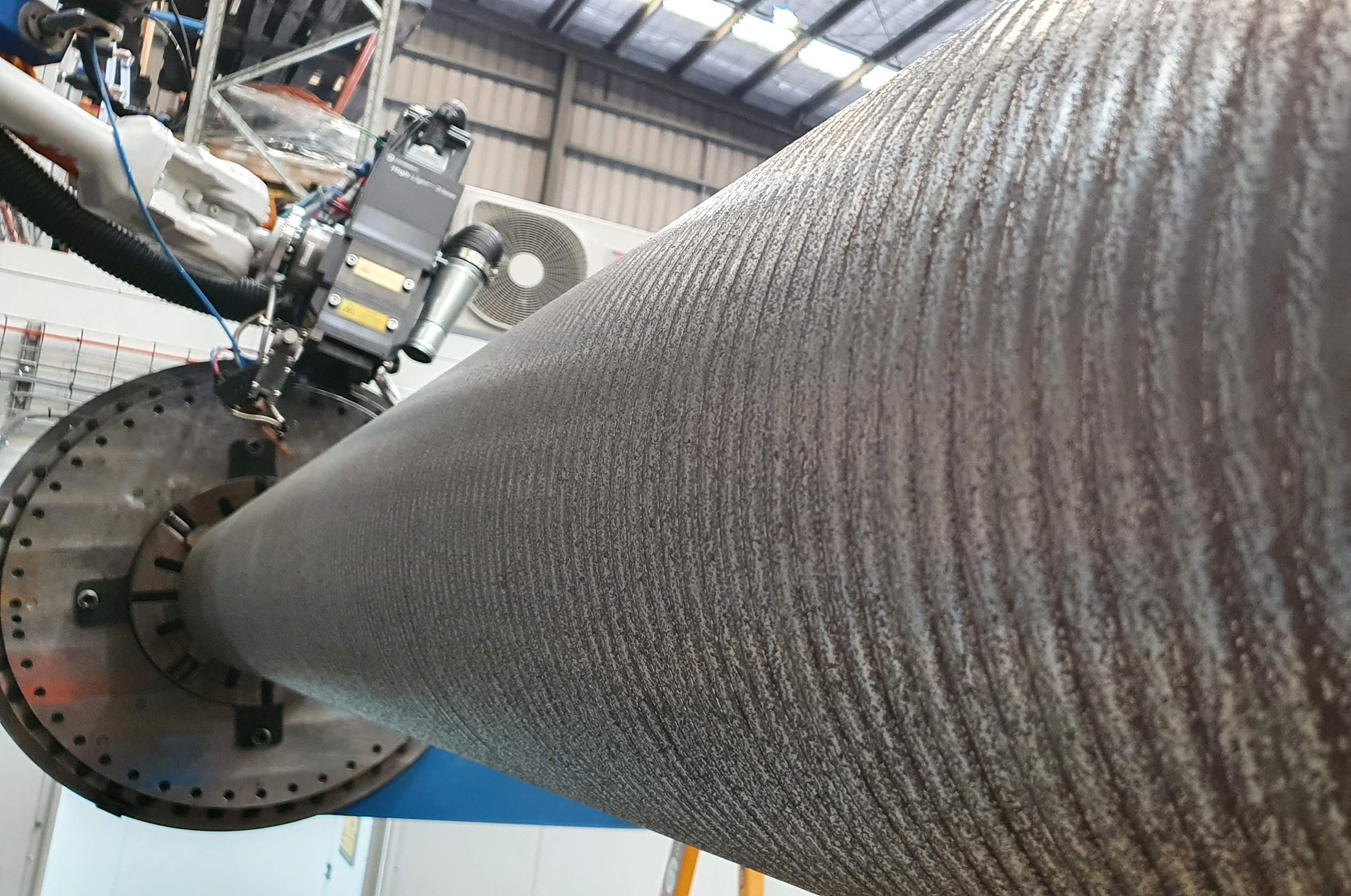

In late 2020 Avweld commissioned our brand new robotic laser cladding system. The high-powered Coherent 10kW direct diode D-series laser unit is the latest and most powerful laser cladding system of its type in Australia. The robotic cell includes capacity for welding 30 tonne jobs, up to 3m diameter and 10m long.

Since then we have commission 2 new laser cladding cells, which utilise smaller fibre-lasers which are suitable for cladding smaller, precision parts, such as internal diameters, small shafts, and edges.

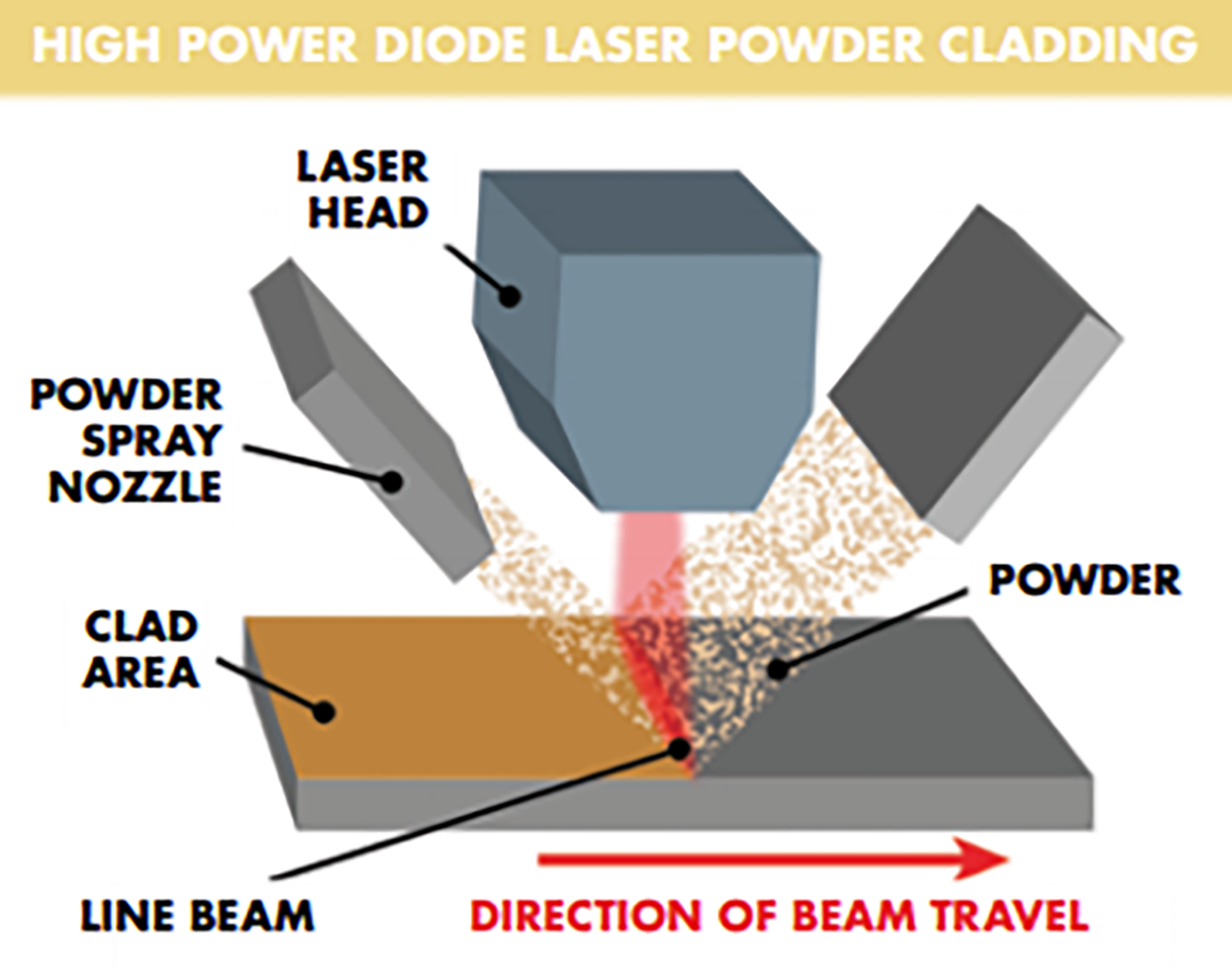

What is laser cladding?

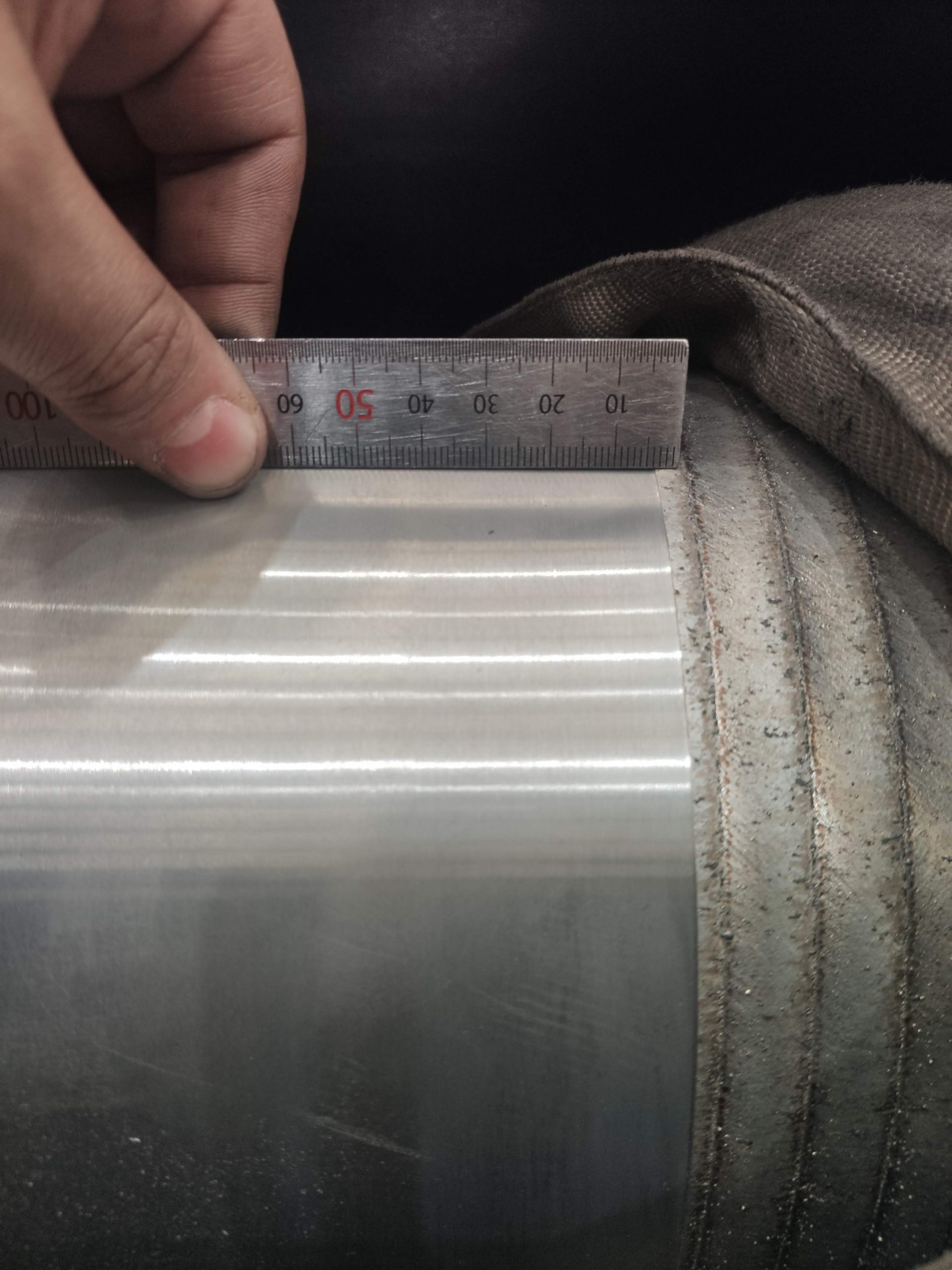

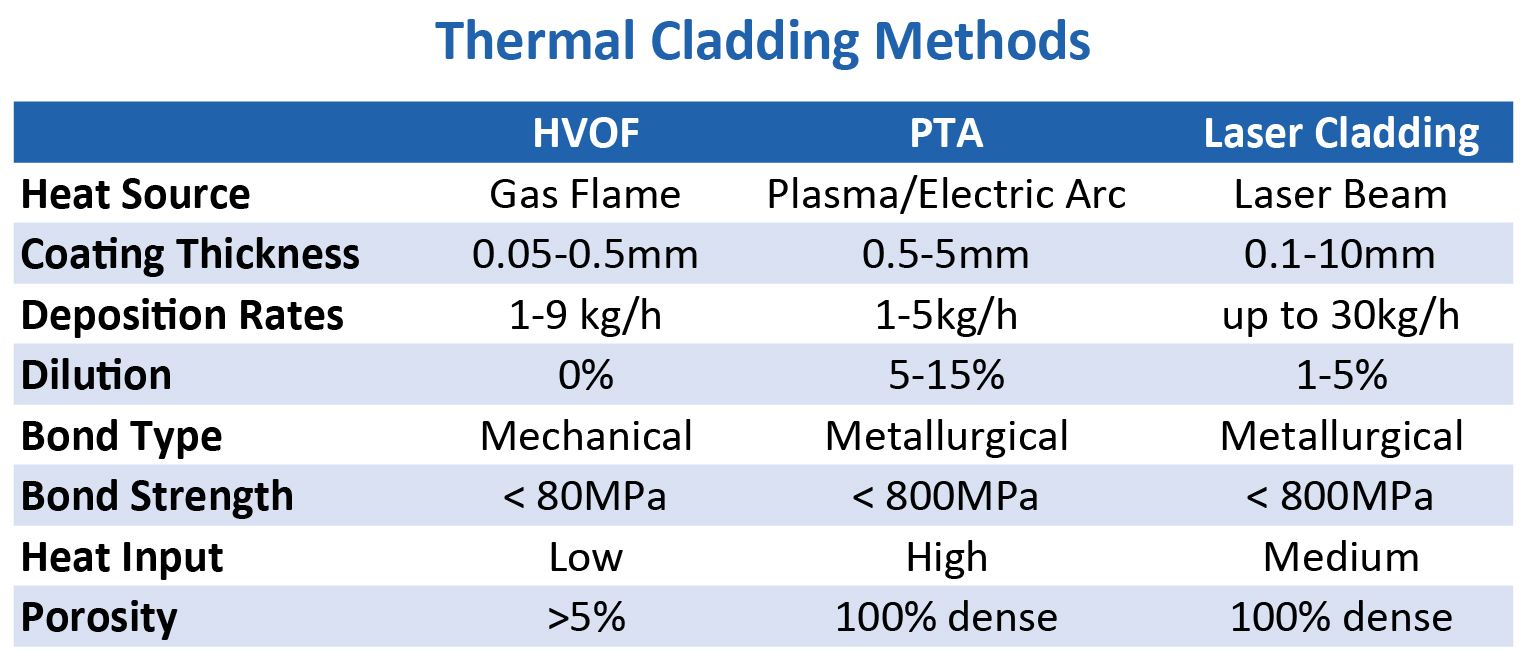

Laser cladding utilises a high powered energy source to melt an additive stock material and weld it to the substrate, providing the advantageous properties of the additive material to the surface. Because the laser energy is so concentrated, it allows for the cladding material to have a full metallurgical bond, without the disadvantages of typical welding processes by minimising heat affected zone (HAZ), dilution and distortion.

Laser cladding is primarily used to apply coatings to parts which are subject to the individual or combined effects of erosion, abrasion, corrosion, or high temperature. It can also be used to dimensionally restore worn components. Common cladding materials include Tungsten Carbide, Nickel and Cobalt Alloys (such as Stellite, Inconel, Hastelloy), Stainless Steel, Iron-Based Hardfacing.

Laser Cladding Advantages

- Metallurgical bond vs. mechanical bond

- Low dilution => 1 – 5% typical (~ 1/3 dilution of PTA process)

- Highly controllable/repeatable and efficient process

- Smooth clad = less post machining

- Small heat effected zone = removes need for post weld heat treatment or stress relief

- High quench rates => finer grain structure => higher corrosion potentials

- High deposit speed compared to thermal spray or PTA.

- High deposit efficiency (>80%)

Applications for High Power Laser Cladding (HPLC)

- Shafts, struts, journals

- Cylinders, rods, rams

- Rollers

- Crusher components

- Drilling and ground-engaging tools

- Wheels, tracks

- Buckets, teeth

- Pipes, chutes, ducts

- Screws, augers

- Wind turbine components

- Boiler tubes

- Cutting blades, knives

- Mulcher and chipper components

- Pump components (sleeves, shafts, impellers, wear rings)

- Valves (stems, discs, seats, balls)

- Gearboxes

- Rotary valves and rotary feeders

- Vacuum pumps

Laser Heat Treatment

Using the same equipment required for laser cladding, by removing the feed stock material, we are able to heat treat surfaces with high efficiency and speed.

Advantages of Laser Heat Treating vs other Technologies

- Precision Control of Heat – Only heat treat desired surfaces

- Minimal Post-Processing – Low distortion – limited post-machining

- Simple “Self-Quenched” Process – Highly repeatable

- Improved Access & Flexibility – Line of sight process – Easy part changeover (software)

- Improved Process Control – Simple, non-contact process – Heating – supports use of optical pyrometer to control the heating.

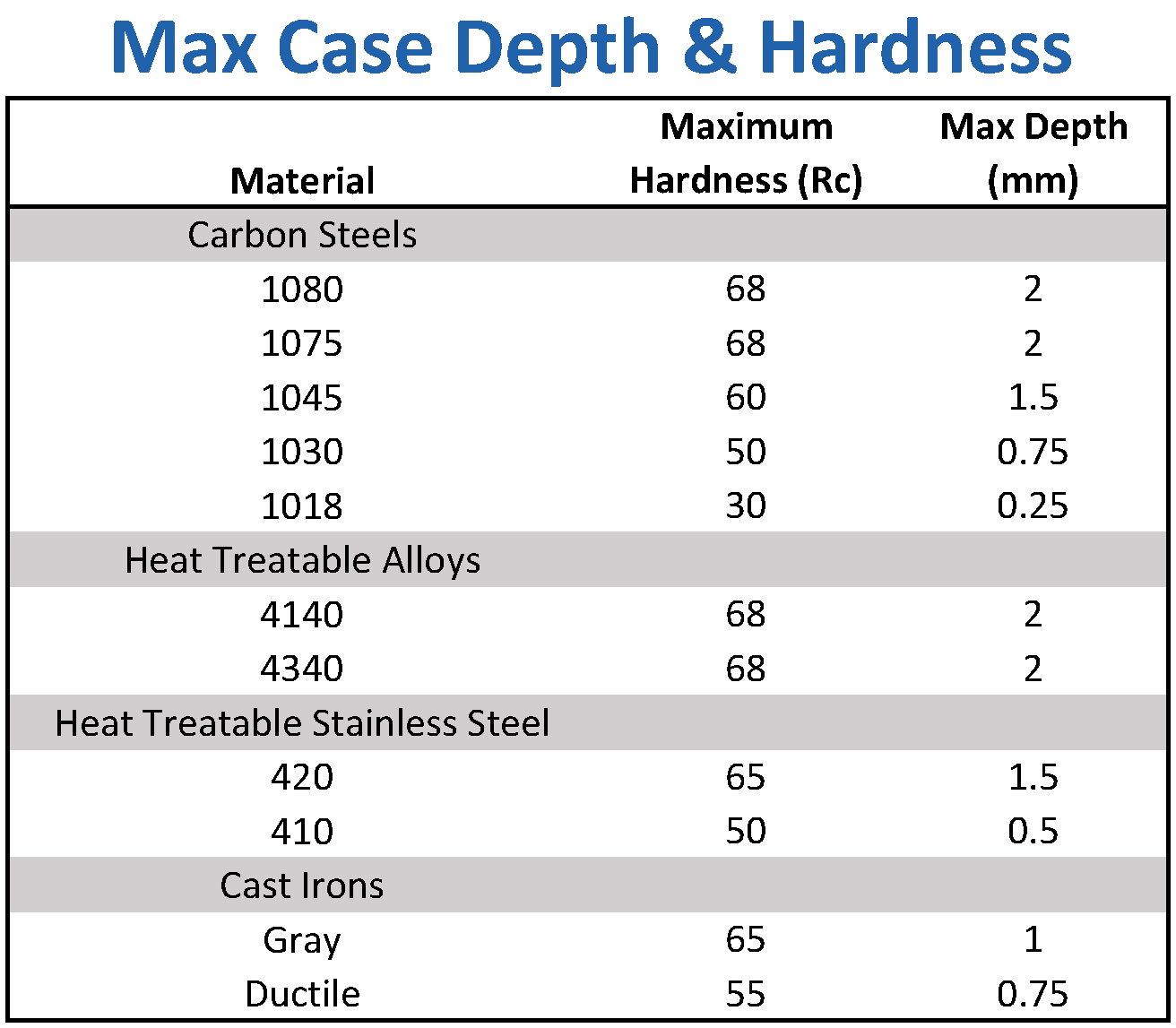

Laser Heat Treatable Materials Carbon & Alloy Steels

(> 0.3% carbon recommended)

- AISI 1030, 1045, 1060, 1075, 1080, 4140, 4340

- Ductile & Grey Cast Iron

- Martensitic Stainless Steels (AISI 410, 420, 440)

Notes:

- Max depth & max hardness for some materials do not coincide

- Actual results are dependent on carbon content and part geometry

- Results are based on direct diode laser system results.