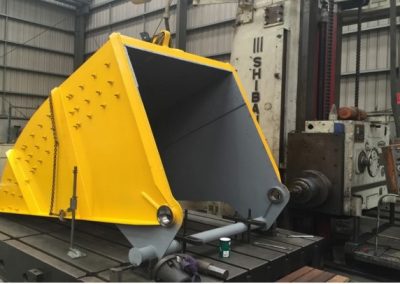

Large-Scale Machining

At our Melbourne Workshop

Avweld have a full machine-shop with some of the largest lathes, mills, grinders and borers available in Victoria. With a very experienced team of tradesmen, we are able to machine and grind all manner of parts to exacting tolerances from very large through to very small.

Having such a broad range of machine tools available in-house enables us to complete overhauls, refurbishment, and new manufacture of all types of parts which require resurfacing.

Our capacities stretch to:

- 6 x lathes, up to 1650 swing x 12m b/w centres

- 6 x cylindrical grinders up to 1700 swing x 12m b/w centres

- 3 x Horizontal borers, up to 3x2x2m work envelope, 30T workpiece weight

- 3 x Vertical Borers, 30T workpiece weight, up to 3m diameter

- 3 x surface grinders, up to 800x1500x400 workpiece

- 3 x manual milling machines

- Drills – up to 1.5×3.1×2.0m

- 6 x Overhead cranes – 10m clearance, 80T total capacity, up to 20T each

Laser Cladding

Laser cladding utilises a high powered energy source to melt an additive stock material and weld it to the substrate, providing the advantageous properties of the additive material to the surface. Because the laser energy is so concentrated, it allows for the cladding material to have a full metallurgical bond, without the disadvantages of typical welding processes by minimising heat affected zone (HAZ), dilution and distortion.