Technology

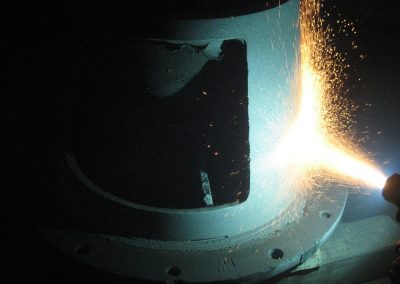

Avweld boasts some of the most advanced material processing systems available in Australia. All of the thermal spray and welding systems incorporate the use of robots. This level of automation ensures the highest quality of coatings, repeatable every time.

Our machine and grinding shop includes some of the biggest equipment in Australia.

| PROCESS | APPLICATIONS |

|---|---|

| Plasma Transferred Arc (PTA) Welding | Tungsten Carbide deposits for extreme abrasion and impact positions |

| DC-Plasma Spray | State-of the art high melting temperature ceramic coatings |

| HVOF Thermal Spray | Versatile wear resistant deposits |

| Loctite Composites | Composite coatings for pumps, and industrial components |

| MIG Welding | Fabrication, general hardfacing |

| Polyurethane coatings | Lightweight tough wear prevention coatings, highly specialised paper industry roll covers, pulley lagging |

| Powder Flame Spraying | Plastic and nylon coatings for specialist rolls in the printing and similar industries |

| Submerged Arc Welding | For large scale fabrication and cladding |

| TIG Welding | Precision hardfacing |

| Twin-wire Arc Spray | Wide variety of metal spray deposits, especially for dimensional restoration, large scale wear prevention, and in-situ processing |